Learning money saving tactics with us...

We will reduce expenses and improve profitability in your Business. Cost-cutting is a measure taken by a company to reduce its expenses and improve profitability.

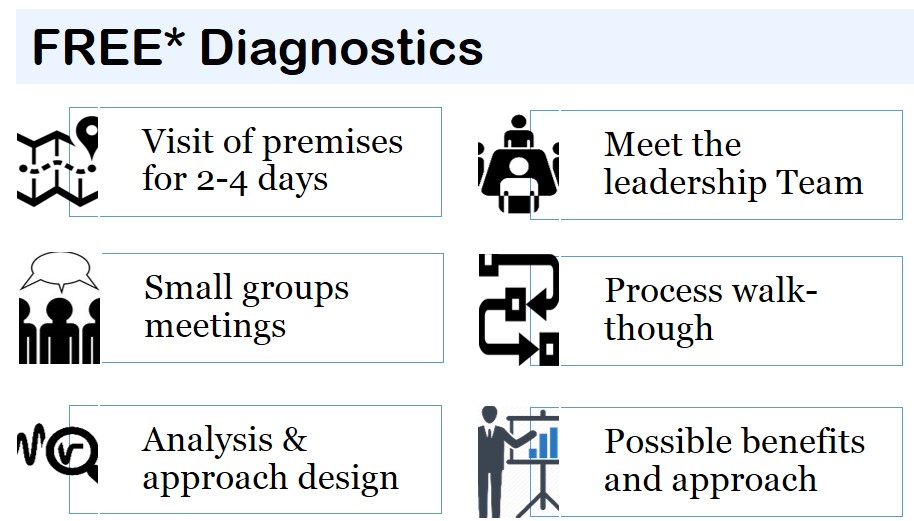

- We customize the solution with a Diagnostic Study and

- present to you the potential savings and proposed solution realize the benefit

* The diagnostic study and presentation is free- only travel, boarding and lodging expenses of the visiting team need to be paid

We focus on levers for –

Maximum business benefits

Simple high-impact solutions

that are

easy to implement and sustain

Get more from less and faster too..

– We help to realize the full potential & best performance of all the available resources

Results Assured

- Marketing expenses reduce 30- 50%

- Brand Development cost reduced in New Area 30-50%

- Cost Optimization: 5-10%

- Productivity Improvement: 20-100%

- Throughput Increase: 10-25%

- Delivery Performance: 30-50%

- Defect Reduction: 25-90%

- Inventory Reduction: 25-90%

- Wastage Reduction: 50-60%

- Product Development cycle Time & Costs: 20-50%

We have a fixed + variable pricing model fees linked to benefits

Improve Profitability and Revenues

Contact us: +91 88899 78785

Email:- rkdixit1969@rediffmail.com

Services & Methodologies

About Us

We are a highly organized and 26 years experience in plant operation & merchandising operations.

Although we are nearly one Year old but we have network of 50 employees at South India especially in Telengana, Andhra Pradesh and Karnataka at different potential cities of steel and cement Market.

Our Team is backed up by a solid and time-tested set of processes and systems for efficient merchandising operations.

We CAN DO because we thrive in a positive environment of teamwork, not just among ourselves, but most especially with our client partners – going to extra miles to execute expectations and standards at point-of-sale, better and better each time.

Love for our clients’ brands and true care for our people are at the core of our existence – we win strategies for our merchandising partners in the steel sector. Know More

Rakesh Kumar Dixit

( Counsellor and Executor of Direct Marketing and Steel Manufacturing )

Mo. No.- +91-88899 78785

Email:-rkdixit1969@rediffmail.com

GSTIN – 36AQ5PD6395F1ZE

Add- Flat.No.402, Maheshwari Residency, Plot.No.328P,329, NJR KLR Nagar, Medchal, Medchal-Mallajgiri Dist, Hyderabad Telangana – 501401

Provide complete solution and Execute in your organization

For Industries

For Plant Operations

For Marketing

- Project Marketing

- Direct Marketing

For Stockists & Dealers

Our Services

Dealer Network

- We will reduce your marketing expenses by 50%, in the initial stage.

- We will appoint Dealer for you.

- We will provide you with zero risk credit policy.

- We will be establishing Brand Image of your product in a new area.

- We will implement your Marketing policy as per your company.

- We will arrange wall or shop painting for brand promotions.

- We will guide you potential market for maximum profit in the minimum time period.

- We will give you Market Survey and scientific analysis.

- We will create demand of your product.

- We will organize meet of Masson/Bar Bender/Engineers/Dealers as per your company policy.

- We will provide after-sales service for customer satisfaction.

- Our Business development officer will continue to monitor the particular area for the development of business.

Project Marketing

- We will prepare documentation and arrange certificate ISO 14001, ISO 18001, ISI 8001.

- We will help you to implementation of ISO system.

- We will help you to arrange meeting of respected authorities for project approval.

- We will arrange project approval.

- We will arrange project order and our Business development officer will continue monitor particular project for order.

Technical & Plant Operation

- Cost optimization.

- Quality Improvement and Defect Free Production.

- Laboratories standardization and calibration.

- How to improve surface finishing of TMT.

- How to increase re-oxidation period 15 day to 45 days of TMT or keeping Grey colure (without Rusting) of TMT.

- Certification of Bureau of Indian standards (BIS).

- Proper Raw Material Analysis and its Standard specification.

- Optimum Yield at Induction Furnace and Rolling Mill.

- Wastage reduction.

- Actual calculation of yield in plant and improve it on day to day basis.

- Standard Operation Procedure at induction furnace.

- Effective Cost calculation of DRI, SMS & Rolling Mill and actual stock assessment on monthly basis.

Methodologies

- Balance scorecard

- Product Portfolio Optimization

- Marketing Strategy

- Static Cost reduction

- Daily Management

- Performance Management

- Continuous Improvement

- Decision making tools

• Business dashboards,

• Management information systems,

• Data science,

• Inferential (Predictive) analytics,

• ERP (real-time information of your business on your phone/tab)

How can I help you?

Provide complete solution and Execute in your plant

QUALITY CONTROL

HOW TO IMPROVE

Consistent Quality Production |

Accurate Incoming Testing |

Zero Breakage of TMT |

Re-oxidation period of TMT |

Surface Fining & Physical defect-free |

BIS Certification & ISO implementation & Certification |

STEEL MELTING

HOW TO IMPROVE

Production |

Furnace life (Silica Ramming Mass ) |

Yield Efficiency. |

Cost efficiency per MT steel. |

Best operation practices. |

Reduce Sulphur & Phosphorus. |

DIRECT MARKETING

HOW TO IMPROVE

Brand Image and increased Profit |

Implement Credit Policy at Zero Risk. |

Advertisement efficiency Reduce Cost of Marketing Expenses |

Develop Dealer Network on advance payment. |

Efficiency of salesperson. |

Growth planning and Marketing strategy implementation. |